A料级聚四氟乙烯

,聚四氟乙烯

,ptfe

,聚四氟

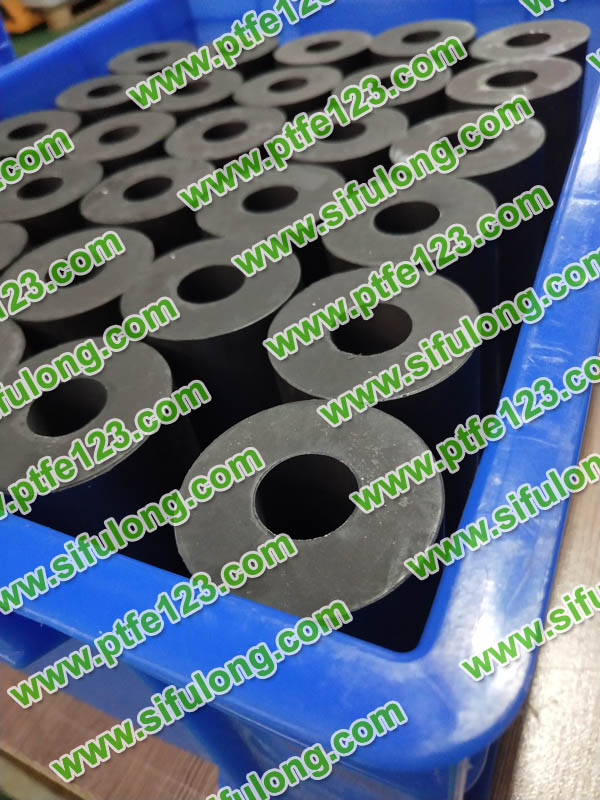

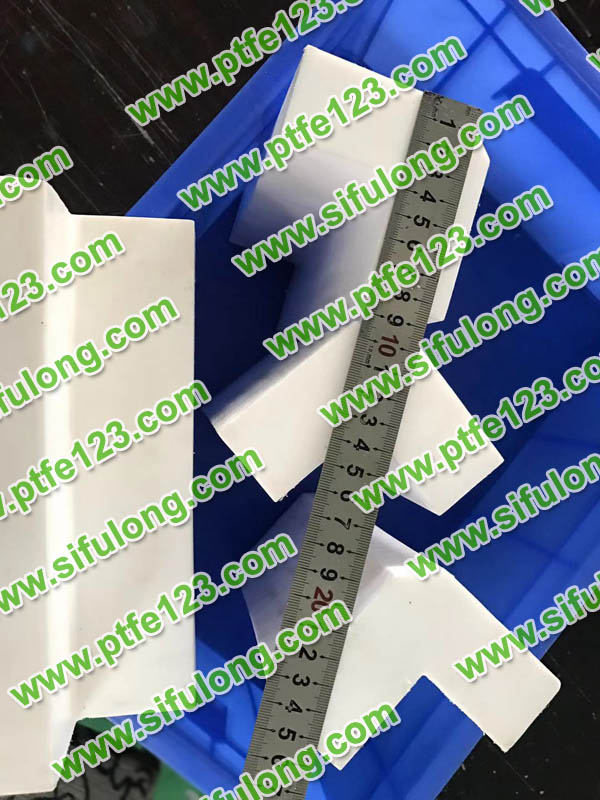

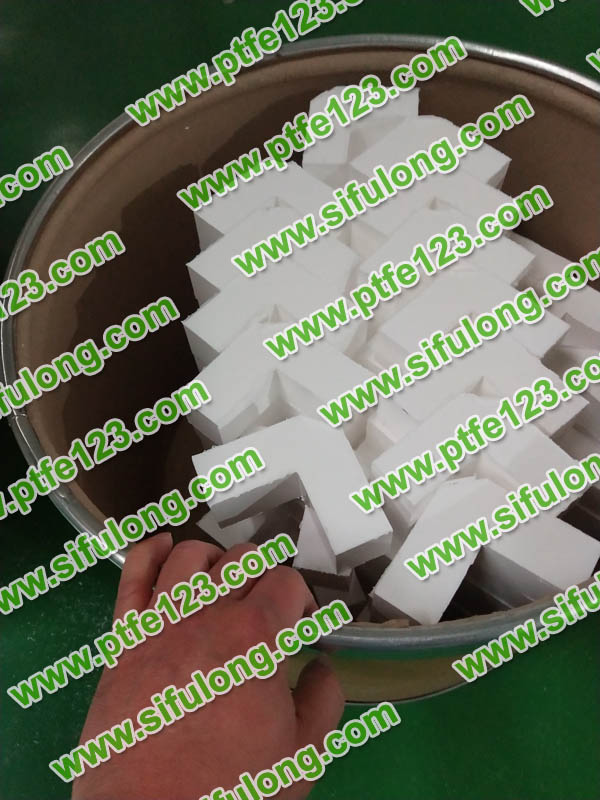

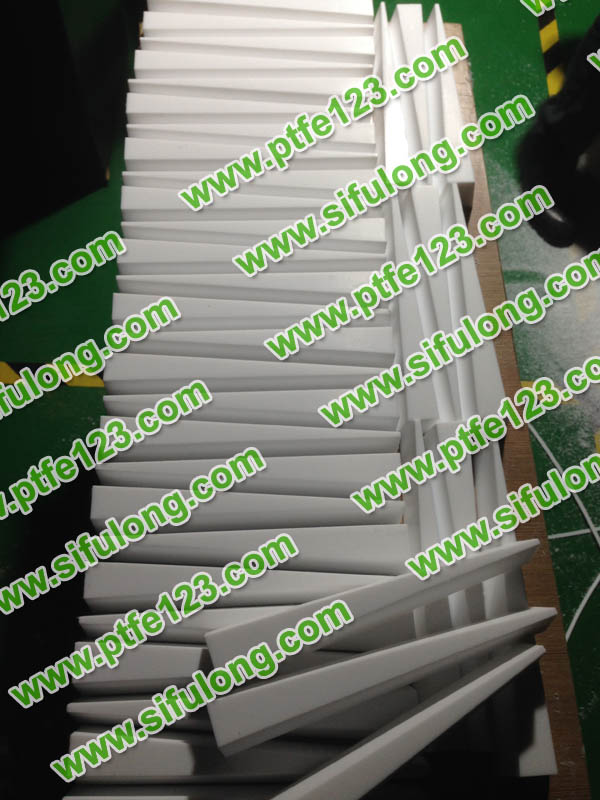

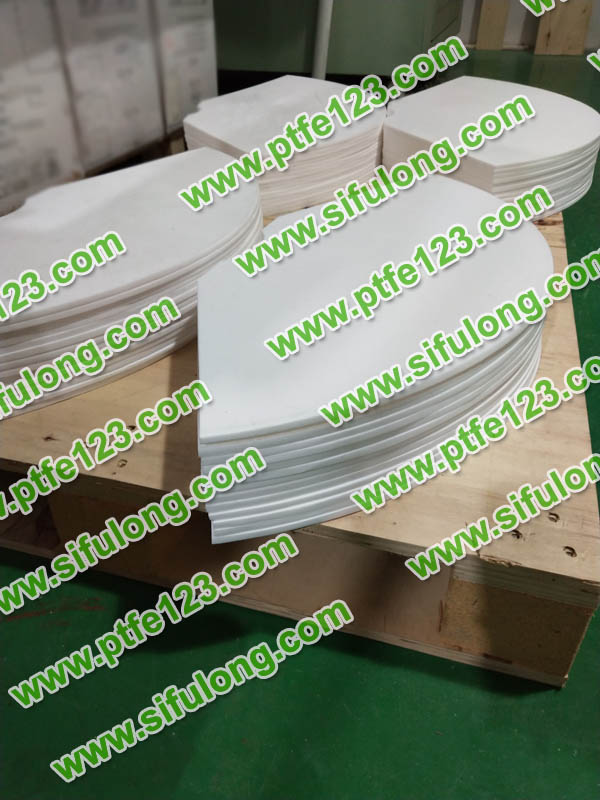

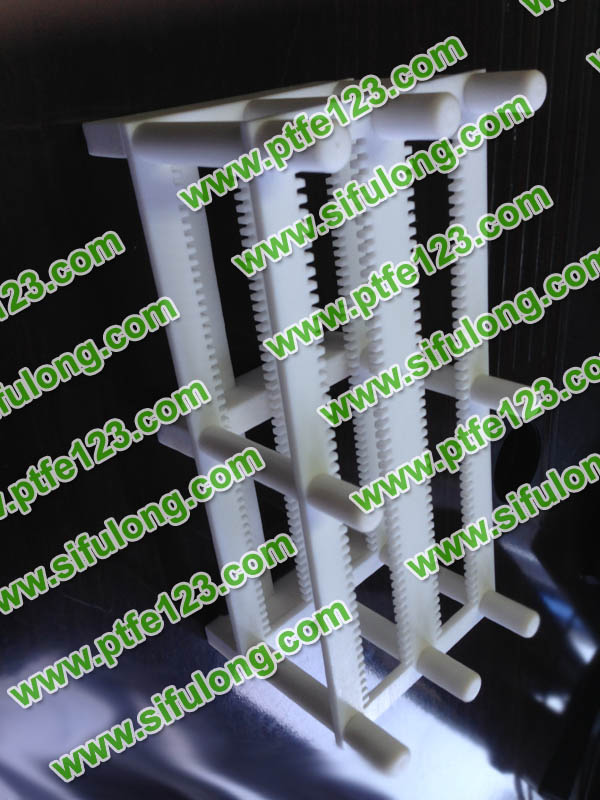

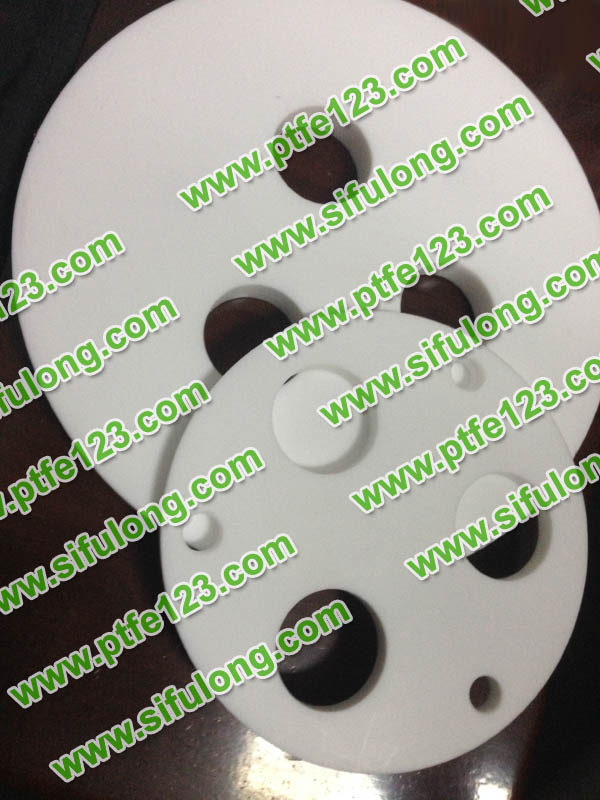

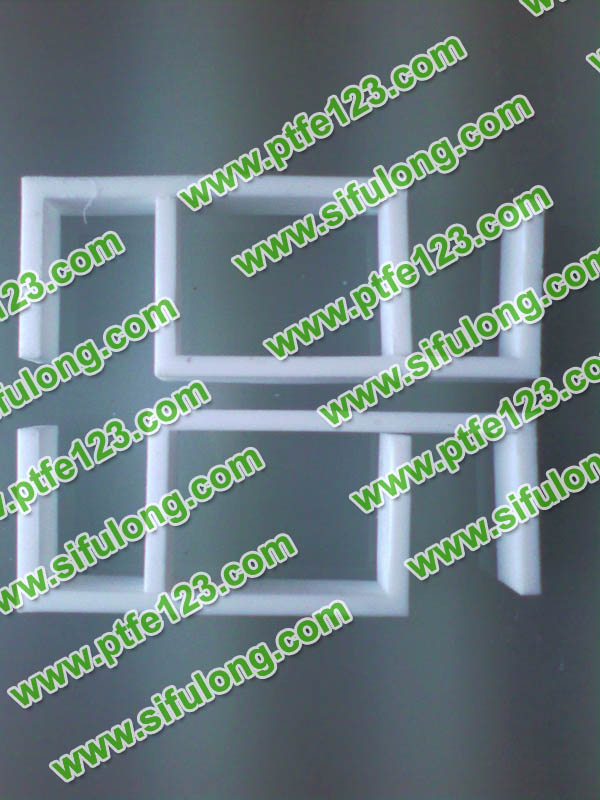

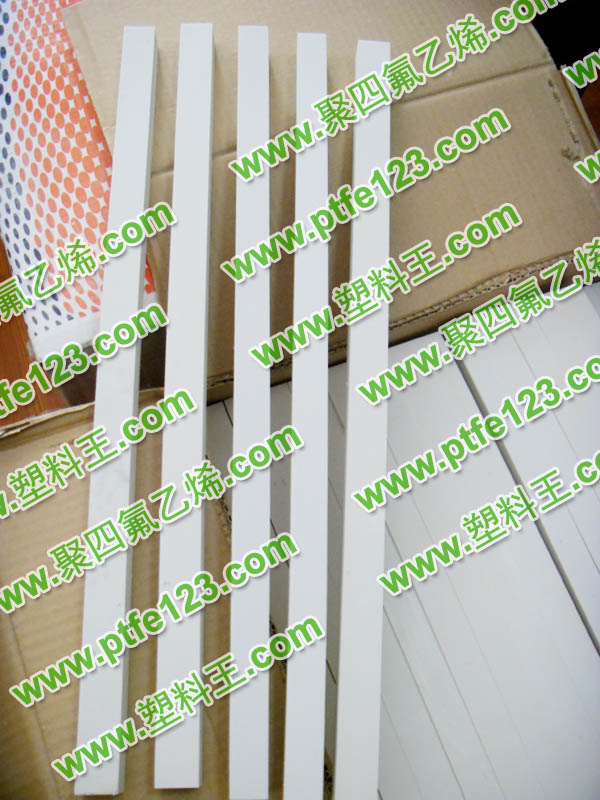

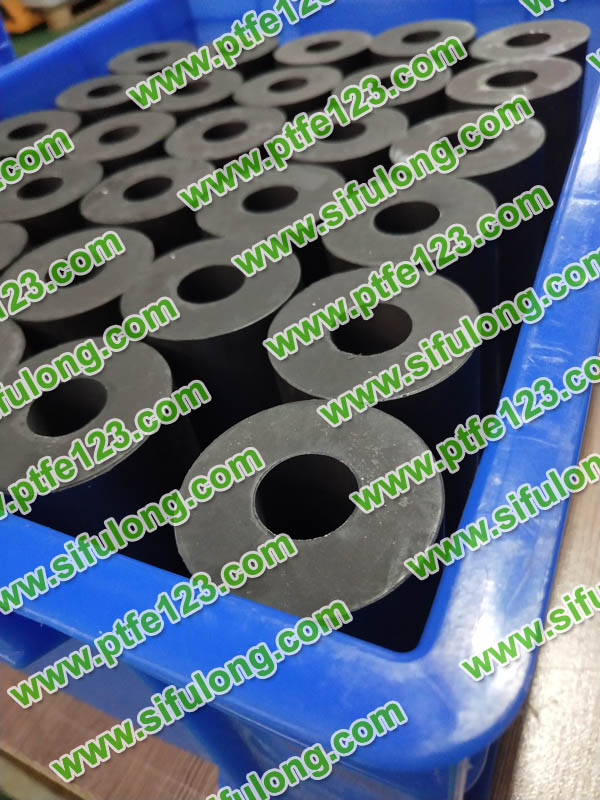

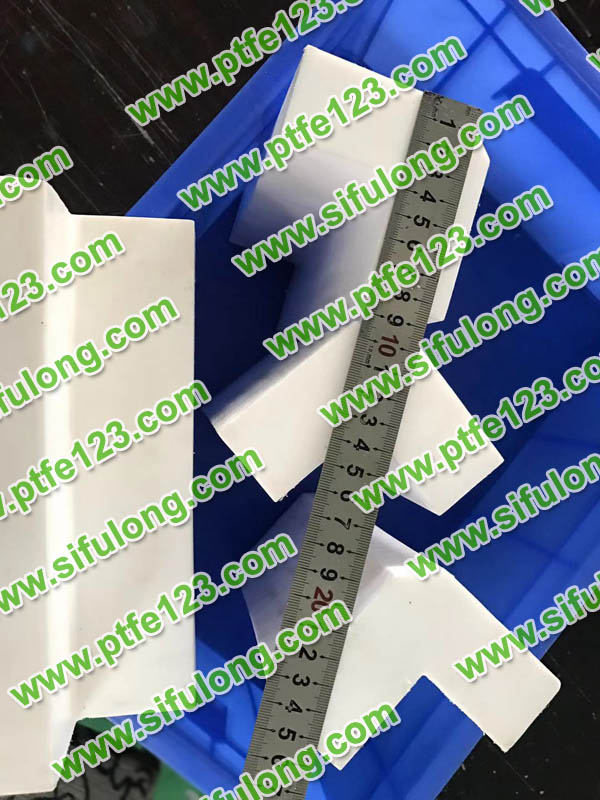

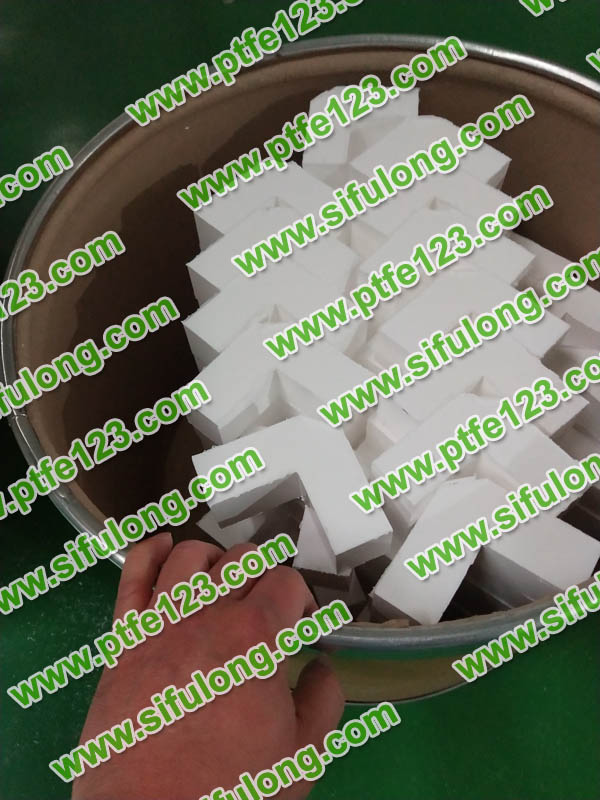

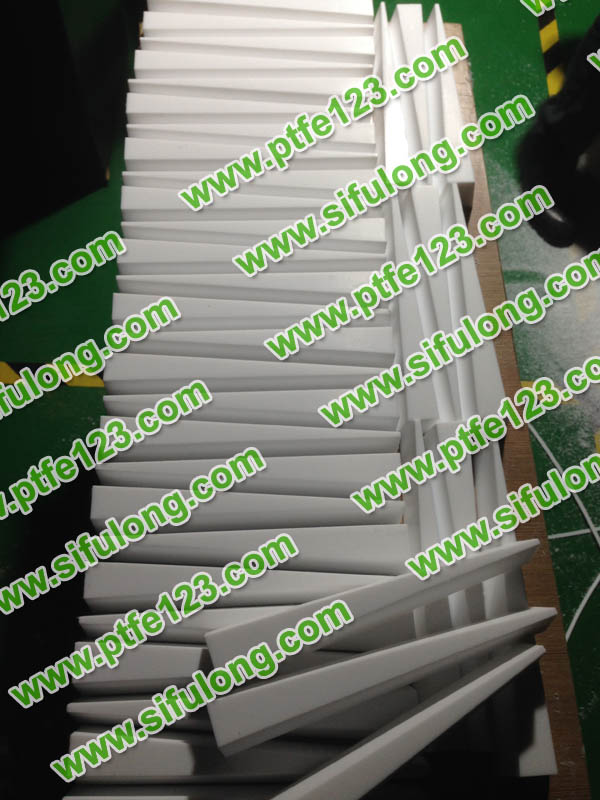

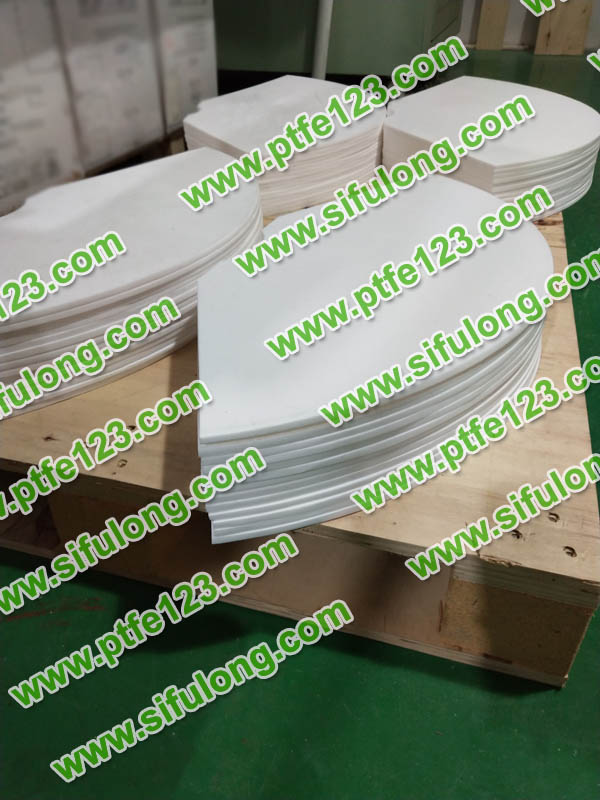

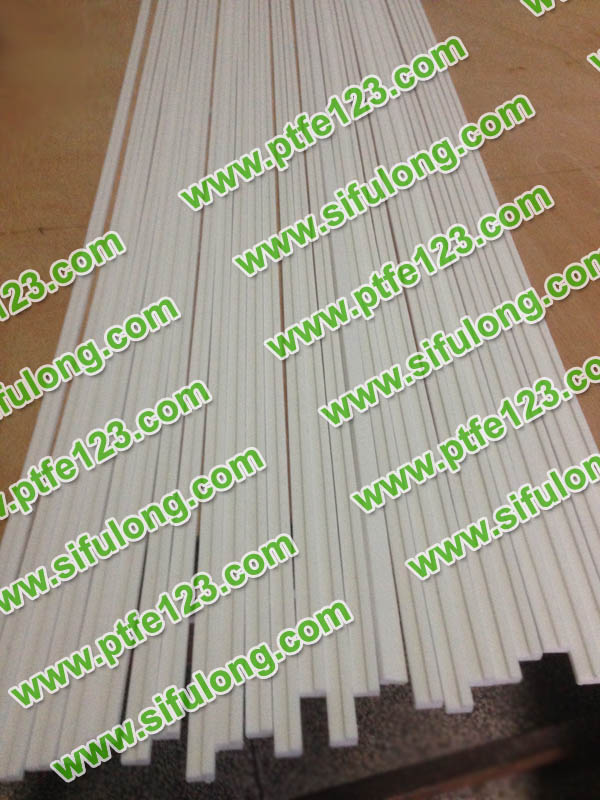

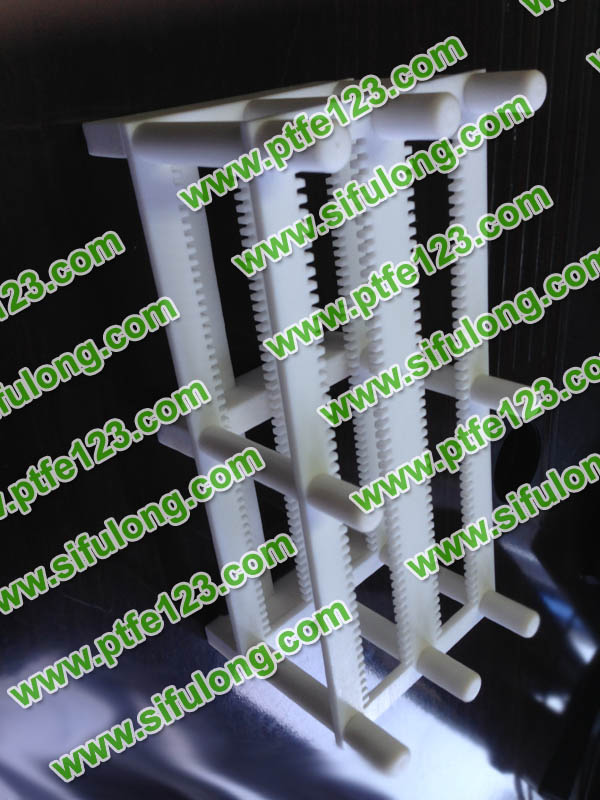

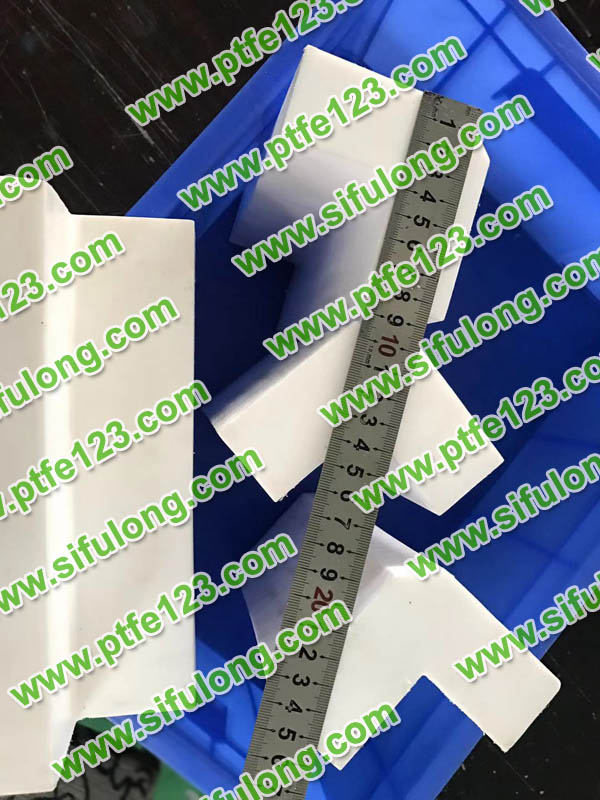

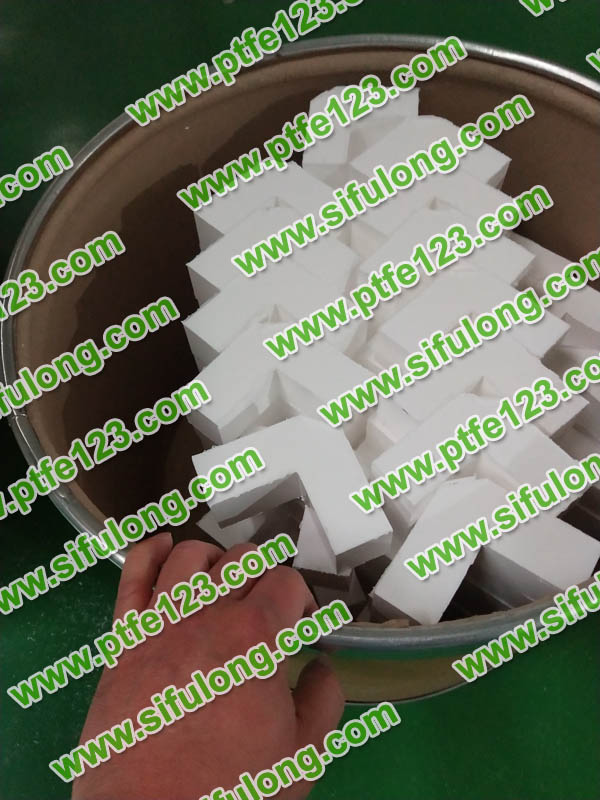

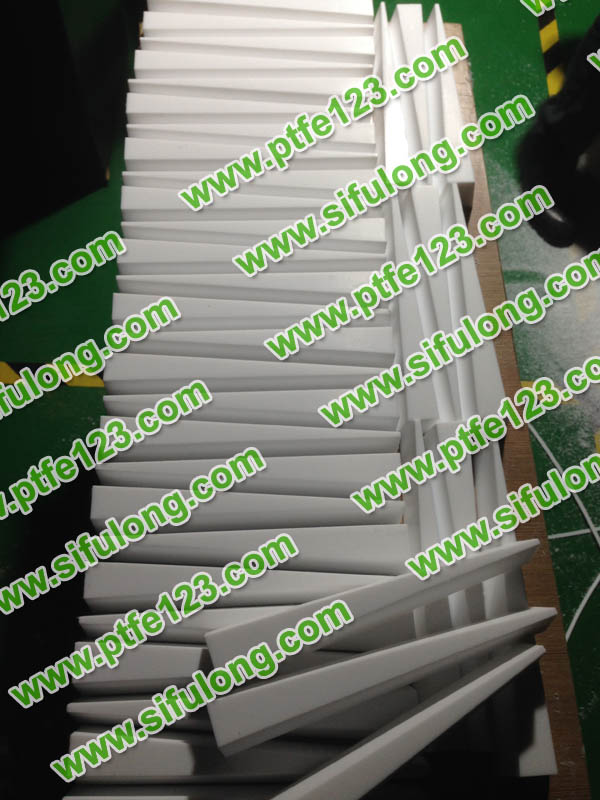

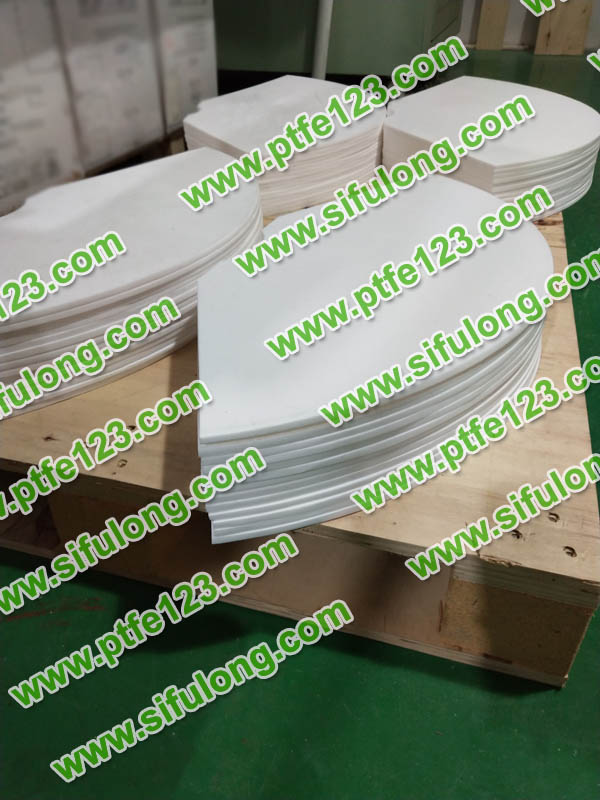

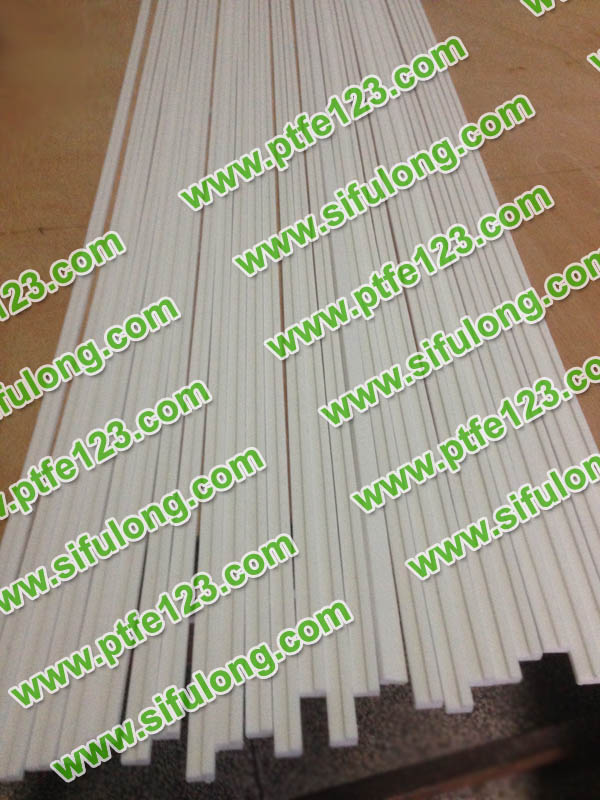

,聚四氟乙烯车削板,聚四氟乙烯薄膜,聚四氟乙烯模压板,聚四氟乙烯模压棒,聚四氟乙烯模压管,ptfe模压板,ptfe模压棒,ptfe模压管,ptfe车削板,ptfe车削膜,PTFE商场,聚四氟乙烯棒,聚四氟乙烯管,聚四氟乙烯垫片,聚四氟乙烯车削膜,聚四氟乙烯挤出棒,ptfe板,ptfe棒,ptfe管,ptfe薄膜,ptfe垫片,ptfe挤出棒,ptfe密封,ptfe制品,ptfe产品,聚四氟乙烯板材,聚四氟乙烯棒材,聚四氟乙烯管材,聚四氟乙烯密封件,聚四氟乙烯产品,聚四氟乙烯ptfe,聚四氟乙烯商场,聚四氟板,聚四氟棒,聚四氟管,聚四氟垫片,聚四氟薄膜,聚四氟车削板,聚四氟密封,聚四氟车削膜,聚四氟制品,聚四氟乙烯购物,聚四氟乙烯,聚四氟乙烯买东西,聚四氟乙烯网购

聚四氟乙烯,PTFE

sheet ptfe,rod ptfe,tube ptfe,plate ptfe,film ptfe,gasket ptfe

ptfe sheet,ptfe rod,ptfe tube,ptfe film,ptfe gasket,ptfe product,PTFE skived sheet,ptfe seal,ptfe extruded rod

PTFE Molded board,PTFE Molded Rod,PTFE Molded Tube,PTFE Molded Products,PTFE Molded tablets

聚四氟乙烯 PTFE 塑料王 四氟龙 ,俗称“塑料王”,是由聚四氟乙烯经聚合而成的高分子化合物,具有优良的化学稳定性、耐腐蚀性、密封性、高润滑不粘性、电绝缘性和良好的抗老化耐力。用作工程塑料,可制成聚四氟乙烯管、棒、带、板、薄膜等。一般应用于性能要求较高的耐腐蚀的管道、容器、泵、阀以及制雷达、高频通讯器材、无线电器材等。

聚四氟乙烯 PTFE 塑料王 四氟龙具有一系列优良的使用性能:耐高温—长期使用温度200~260度,耐低温—在-100度时仍柔软;耐腐蚀—能耐王水和一切有机溶剂;耐气候—塑料中最佳的老化寿命;高润滑—具有塑料中最小的摩擦系数(0.04);不粘性—具有固体材料中最小的表面张力而不粘附任何物质;无毒害—具有生理惰性;优异的电气性能,是理想的C级绝缘材料,报纸厚的一层就能阻挡1500V的高压;比冰还要光滑。聚四氟乙烯材料,广泛应用在国防军工、原子能、石油、无线电、电力机械、化学工业等重要部门。产品:聚四氟乙烯棒材、管料、板材、车削板材。聚四氟乙烯是四氟乙烯的聚合物。英文缩写为PTFE。结构式为:CF3(CF2CF2)nCF₃。20世纪30年代末期发现,40年代投入工业生产。性质 聚四氟乙烯相对分子质量较大,低的为数十万,高的达一千万以上,一般为数百万(聚合度在104数量级,而聚乙烯仅在103)。一般结晶度为90~95%,熔融温度为327~342℃。聚四氟乙烯分子中CF2单元按锯齿形状排列,由于氟原子半径较氢稍大,所以相邻的CF2单元不能完全按反式交叉取向,而是形成一个螺旋状的扭曲链,氟原子几乎覆盖了整个高分子链的表面。这种分子结构解释了聚四氟乙烯的各种性能。温度低于19℃时,形成13/6螺旋;在19℃发生相变,分子稍微解开,形成15/7螺旋。

虽然在全氟碳化合物中碳-碳键和碳-氟键的断裂需要分别吸收能量346.94和484.88kJ/mol,但聚四氟乙烯解聚生成1mol四氟乙烯仅需能量171.38kJ。所以在高温裂解时,聚四氟乙烯主要解聚为四氟乙烯。聚四氟乙烯在260、370和420℃时的失重速率(%)每小时分别为1×10-4.4×10-3和9×10-2。可见,聚四氟乙烯可在 260℃长期使用。由于高温裂解时还产生剧毒的副产物氟光气和全氟异丁烯等,所以要特别注意安全防护并防止聚四氟乙烯接触明火。

聚四氟乙烯防腐蚀产品可以替代大量合金材料制品,增加设备工作能力,减少停工维修,是一种很有开发潜力的耐腐蚀产品。

聚四氟乙烯 PTFE 塑料王 四氟龙 在原子能、国防、航天、电子、电气、化工、机械、仪器、仪表、建筑、纺织、金属表面处理、制药、医疗、纺织、食品、冶金冶炼等工业中广泛用作耐高低温、耐腐蚀材料,绝缘材料,防粘涂层等,使之成为不可取代的产品。

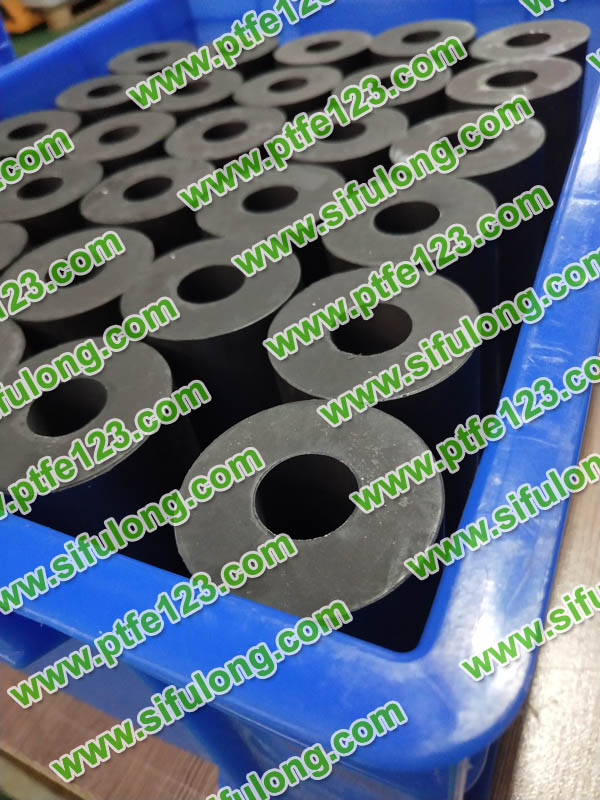

聚四氟乙烯具有杰出的优良综合性能,耐高温,耐腐蚀、不粘、自润滑、优良的介电性能、很低的摩擦系数。用作工程塑料,可制成聚四氟乙烯管、棒、带、板、薄膜等,一般应用于性能要求较高的耐腐蚀的管道、容器、泵、阀以及制雷达、高频通讯器材、无线电器材等。在PTFE中加入任何可以承受PTFE烧结温度的填充剂,机械性能可获得大大的改善,同时保持PTFE其它优良性能。填充的品种有玻璃纤维、金属、金属化氧化物、石墨、二硫化钼、碳纤纤、聚酰亚胺等,耐磨耗、极限PV值可提高1000倍。

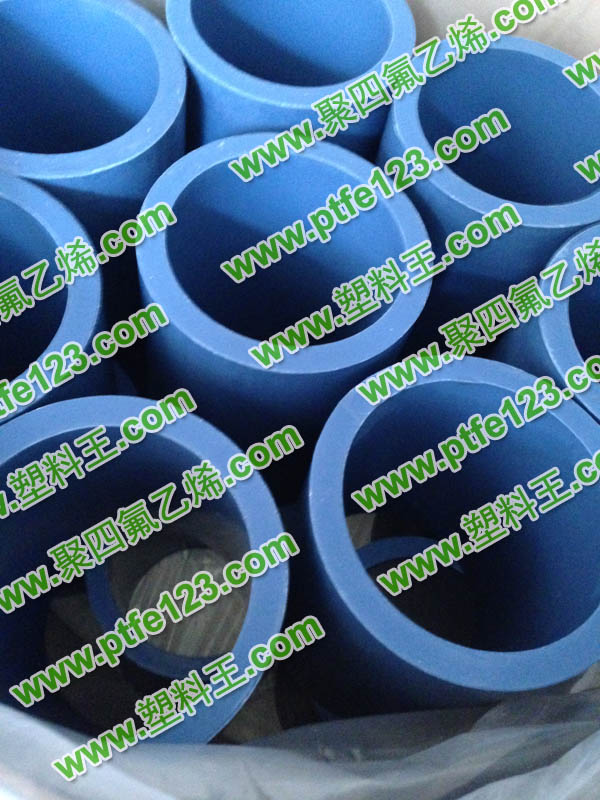

聚四氟乙烯管材选用悬浮聚合聚四氟乙烯树脂经柱塞挤压加工制成。在已知塑料中聚四氟乙烯具有最好的耐化学腐蚀性能及介电性能。聚四氟乙烯编织盘根是一种良好的动密封材料,是由膨体聚四氯乙烯带条编织而成,具有低摩擦系数、耐磨、耐化学腐蚀、密封性良好、不水解、不变硬等优良性能。用于各种介质中工作的衬垫密封件和润滑材料,以及在各种频率下使用的电绝缘件、电容器介质、导线绝缘、电器仪表绝缘等。聚四氟乙烯 薄膜适用于作电容器介质、 特种电缆的绝缘层、导线绝缘、电器仪表绝缘及密封衬垫,还可做不粘带、密封带、脱模。 此外,生活中用的不粘锅的内衬也使用聚四氟乙烯制作的,就是利用了聚四氟乙烯耐高温,不粘的特点。

聚四氟乙烯|

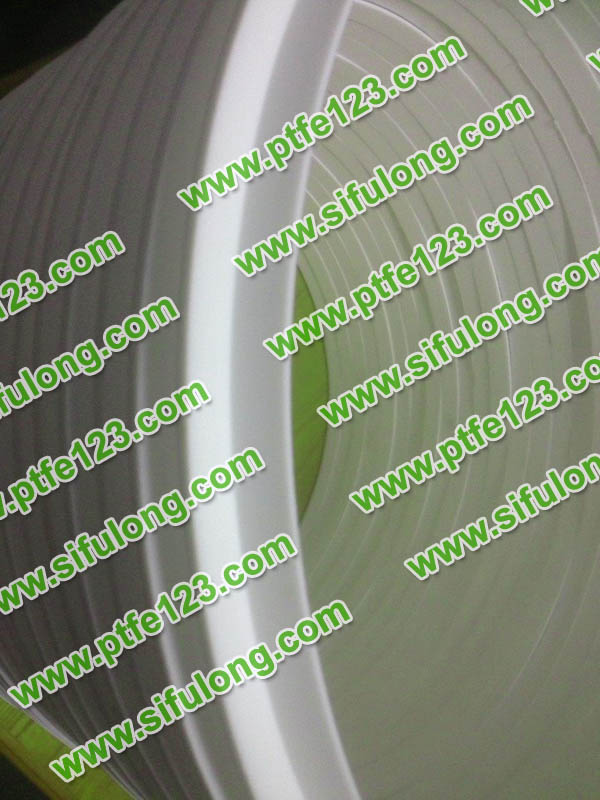

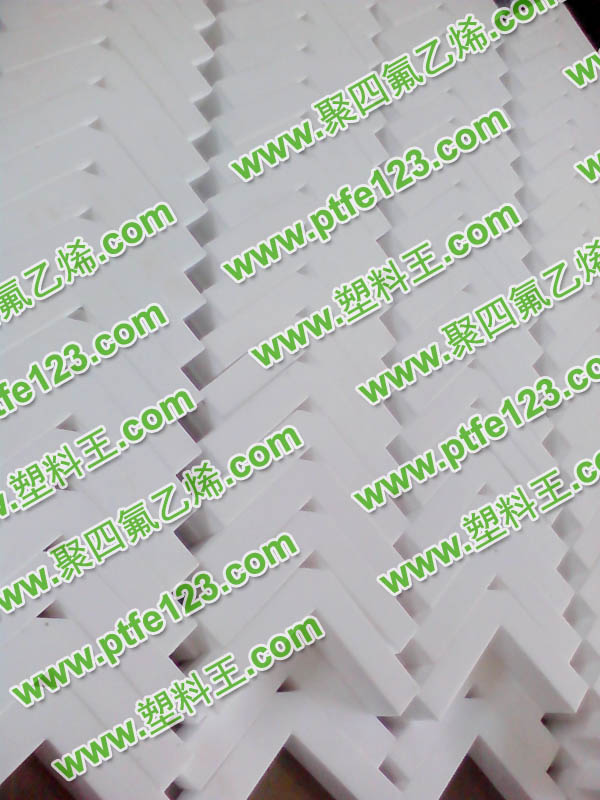

聚四氟乙烯板|

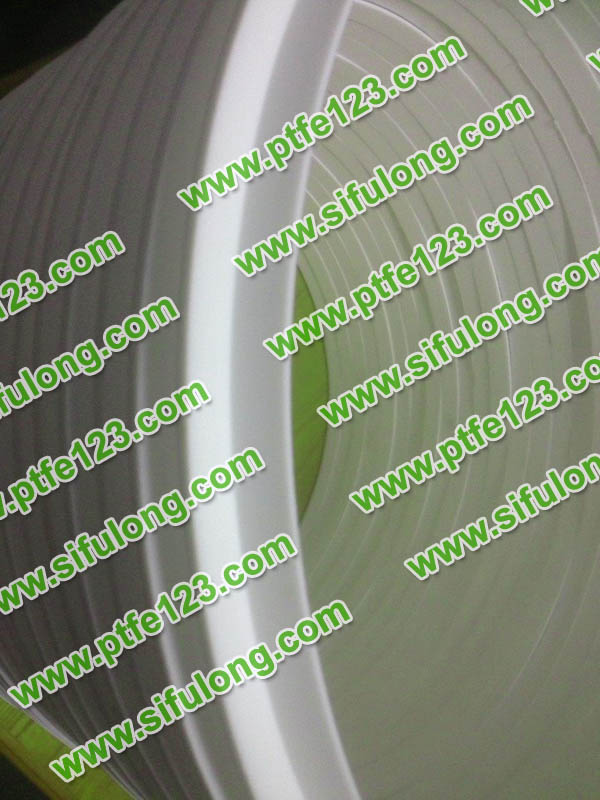

聚四氟乙烯薄膜|

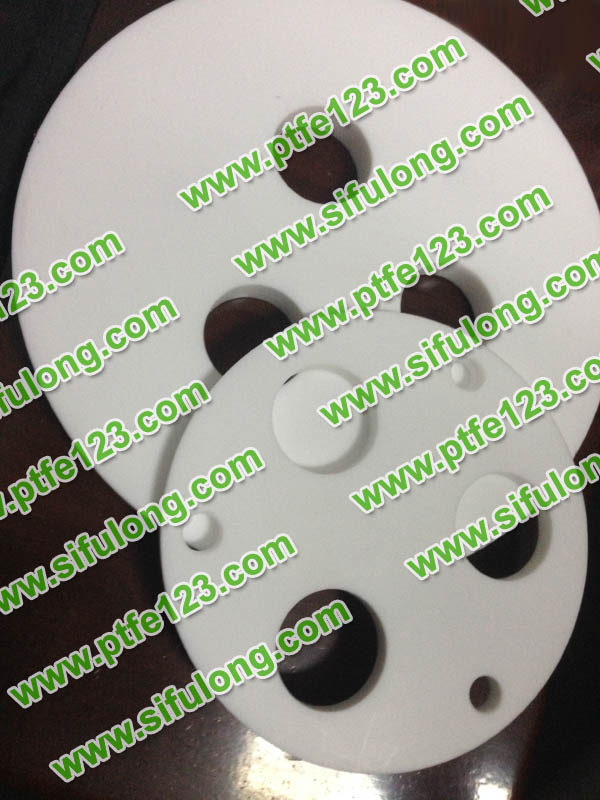

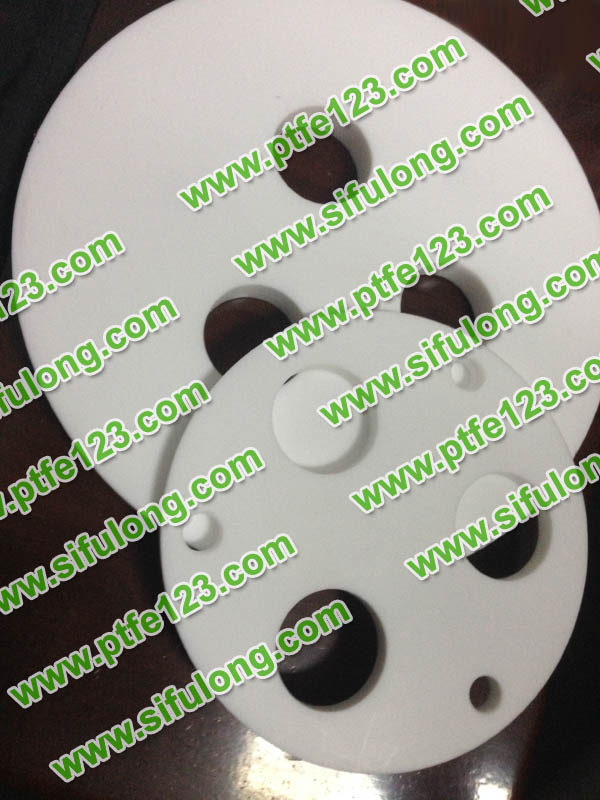

聚四氟乙烯垫片|

聚四氟乙烯管|

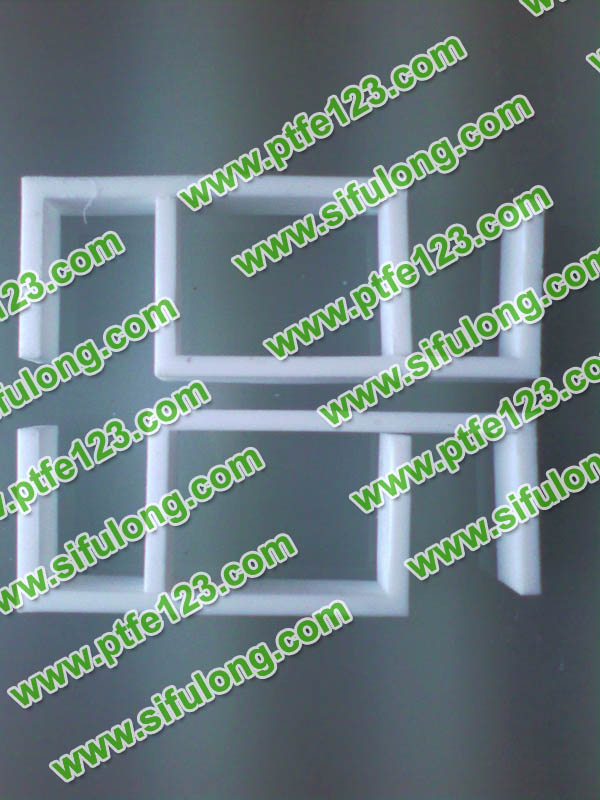

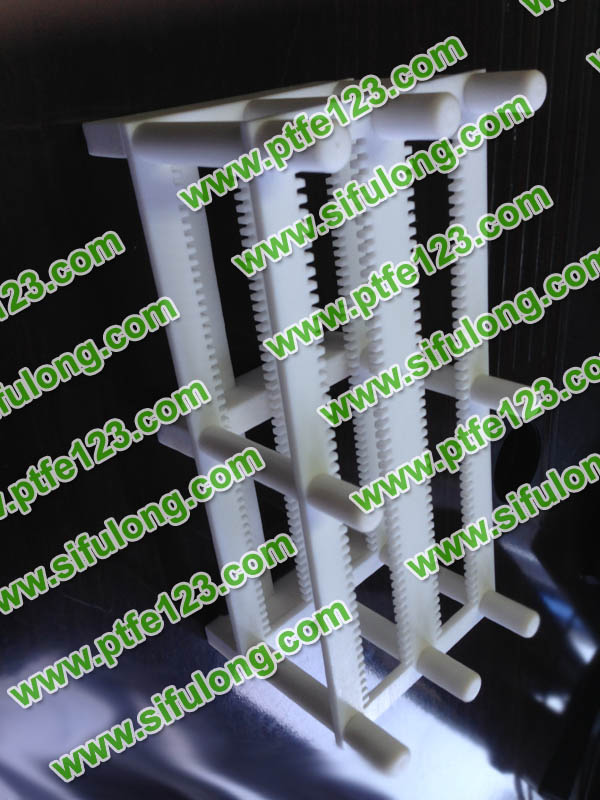

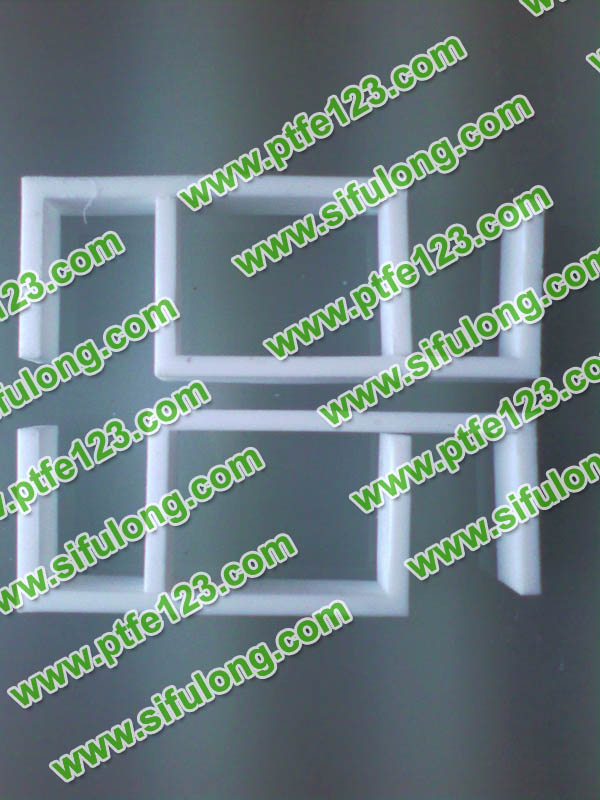

聚四氟乙烯制品|

聚四氟乙烯棒|

聚四氟|

塑料王|

塑料王国|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟|

聚四氟乙烯|

四氟|

PTFE|

聚四氟乙烯|

四氟龙|

聚氟龙|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

四氟龙|

四氟龙|

四氟龙|

四氟龙|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

PTFE|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯|

聚四氟乙烯